Knife Edge Gate Valve

Cylinder - Pneumatic Operated Knife Edge Gate Valves Manufacturer In India

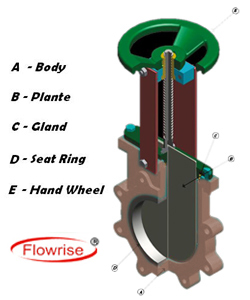

“FLOWRISE” Brand Knife Edge Gate Valves..

“FLOWRISE” brand Knife Edge Gate Valve is the specific design. This design ensures minimum contact between the parts of the valve, Reduces the wear & tear. The high performance Knife Edge Gate Valves feature. Non Sliding Motion, Avoid Sliding Contact between Body & Gate allow flushing of media form the valve interior. A wide variety of hardened trim options are available on Gate, Seat and Wear Ring. Batten edge of the gate (knife-edge) allows the tight shut off even when solid particles settles at the bottom of the Body.

Knife Edge Gate Valves Supplier

Knife-Edge Gate Valves in Mining, Power, Steel, Chemical, Paper and withstand high Temperature & Abrasive Slurries in Industries Ideal for high-density slurry lines.

Knife Gate Valves are Unidirectional Valves, Excellent Hopper Isolation Valves with their ability to cut through flowing media and closed by dislodging any material in the seating area. Knowing us as a reputed firm, Beena Engineering Works are engaged in manufacturing, supplying, as well as dealing a wide range of Knife Edge Gate Valves in Ahmedabad, Gujarat, India.

Type’s of Knife Edge Gate Valves in Gujarat

| Edge Gate Valves. | Uni-directional / Bi-directional Knife Edge Gate Valve | ||||||||

| Body/Gate/Seat M.O.C. | Cast Steel / Cast Iron / S.G.Iron/SS 304 / 316 / 316L.

|

||||||||

| Port Type : | Round Port, Lugged Type. | ||||||||

| Valve End Connection : | Flange End / Uni Lugged, Wafer , Two Lug, Wafer Flange-less, | ||||||||

| Sizes : | 50mm T0 800mm | ||||||||

| Rating : | 10 bar up to 800mm for valves with body in C.S., S.S. and specially alloy, 10 bar Up to 300mm & 5 bar on higher sizes up to 800mm with body in Cast Iron / Ductile Iron. | ||||||||

| Drilling : | Option Include ANSI, DIN, BS, JIS and AS standard; others on request | ||||||||

| Operation Available : | Knife edge Gate Valves Operation – Manual, Cylinder Operated, Electrical Actuator, Pneumatic Actuator with Manual Override. | ||||||||

| Widely Used For | “FLOWRISE” Brand Knife Edge Gate Valves for Slurry Lines, Sludge and Viscous Media Handling, Pulp and Paper Stock Lines, Dry Solid and Powder Handling, High Temperature Gas Lines and Many More. |

Knife Edge Gate Valve

“FLOWRISE” Brand Solid cast knife-edge gate valve provides value and performance with many standard features , commodity knife-edge gate valve. Flowrise Knife edge gate valve is one of the specific design among industrial valves and generally Uni-Directional design with solid cast single wafer, full lugged, two lugs and flanged type body, renewable seat type, rugged stainless steel gate around on both sides for lasting wear resistance, increased packing life and smooth operation. A wide variety of hardened trim options are available on gate & seat ring.

Manual Override

“FLOWRISE” offers a manual hand operation facility with cylinder actuator.

Application

“FLOWRISE” Brand Knife-edge gate valves are widely used in various application such as Mining’s Collieries, Cement, Plup, Paper, Thermal Power Plants, Stock Lined, C.S. Plant for High temperature gas lines, Dry solid power handling such as polymer chips handling. Chemical Sledges, Sewage and waste water treatment, sticky media and molasses for sledge and viscous media handling, Steel plant, Fly ash, Sugar Industries, powders, Clean or Corrosive gases.

Selection of Body Material

Seat Material

Gate Material

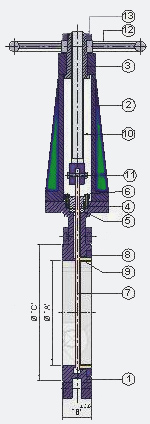

Wheel And Ring Type, Knife Gate Valve

| 1. | Body-Cast Iron / Cast Steel / SS 304 / SS 316 |

| 2. | Frame- M.S |

| 3. | Gate – S.S .304 |

| 4. | Spindle – S.S. 304 |

| 5. | Wheel CI |

| 6. | Spindle Nut Gun Metal |

| Size | A | B | P.C.D | H | J | K |

| 40 | 315 | 35 | 98 | 125 | 355 | 1/2″ |

| 50 | 335 | 40 | 114 | 125 | 385 | 1/2″ |

| 75 | 385 | 45 | 146 | 175 | 460 | 1/2″ |

| 100 | 458 | 50 | 178 | 200 | 558 | 1/2″ |

| 125 | 508 | 55 | 210 | 200 | 633 | 1/2″ |

| 150 | 564 | 60 | 235 | 250 | 714 | 5/8″ |

| 200 | 706 | 65 | 292 | 300 | 906 | 5/8″ |

| 250 | 815 | 68 | 356 | 300 | 1065 | 5/8″ |

| 300 | 885 | 70 | 406 | 350 | 1185 | 3/4″ |

Gland Packing

P.T.F.E. Impregnated Asbestos yarn suitable for maximum temperature up to 1210 C. Square Graphite Asbestos yarn, suitable for temperature up to 1210 C And pressure 150 psi Pure P.T.F.E. suitable up to temperature up to 4500 F and pressure maximum 150 psi

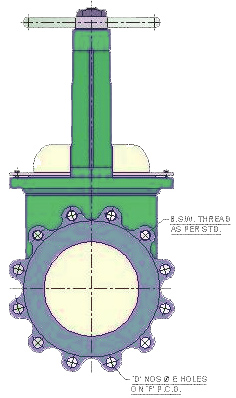

Valve End Style

Full Lugged / Two Lugs wafer style with BSP thread hole is the chest area and Lugs Full Lugged / Two Lugs wafer style with BSP thread hole is the chest area and Through hole is Lugs.

Design & Testing

MSS SP 81 applies only to bonnet less metal-seated knife gate valves, 2” to 24” size, 150 psi CWP.

Pneumatic Acutators

“FLOWRISE” Brand Cylinder Actuators provide a versatile method to automate Knife Edge Gate Valve. Air and Hydraulic cylinder actuators from Flow-age provide a versatile and cost effective method of automation. This adds up to a greater value for you. We offers different types of Cylinder Actuator suitable for Knife Gate & Slide Gate Valve. Cylinder Actuator is a double acting design and is available in a wide range of cylinder diameter and stroke lengths.

- Standard cycle duty Air cylinder up to 8 bar rated

- Specialized Heavy duty Hydraulic cylinder up to 210 bar rated

- Specially design for high cycle duty Air cylinder up to 15 psi rated

Type: Double Acting

Limit Switches

Soenoid Valve

I/P Converter

Air Filter Regulator

Pneumatic Tubing & Fittings

Speed Control Valve

| Body | MSS SP-81 requires the valve body (pressure vessel and related structure) to designed for and hydrostatically pressure tested to 1.5 times the rated working pressure

|

| Gate | MSS SP-81 requires the gate to be designed for and hydrostatically pressure tested to 1.1 times the rated working pressure

|

| Seat | MSS SP 81 has an allowable leakage rate (for metal to metal seated valves) of 40 cc per inch of diameter, per minute at 40 psi pressure. On a 12” valves this would be equal 40 times 12, or 480 cc per minute at 40 psi.

|

| Face To Face | MSS-SP-81 has specified face-to-face dimension and tolerance of each valve size to assure ease of installation for the consumer, regardless of the valve manufacturer. See catalogue for dimension. |

| No. | Body Parts Name | M.O.C. of Parts |

| 1. | Body | C.I./WCB/CF8/CF8M / Duplex |

| 2. | Yoke | C.I./WCB/CF8/CF8M |

| 3. | Yoke Bush / Sleev | C.S. |

| 4. | Disc | S.S. 304 / 316 |

| 5. | Gland | C.I./WCB/CF8/CF8M |

| 6. | Gland Stud & Nut | C.S. |

| 7. | Gland Packing | Graphite / PTFE |

| 8. | Seat | Soft / Metal |

| 9. | Seat Ring | CF8 / CF8M |

| 10. | Seam / Spindle | S.S. 304 / 316 |

| 11. | Spindle Pin / Stud & Nut | S.S. 304 / 316 |

| 12. | Nut | C.S. |

| 13. | Wheel | C.I. |

| 14. | Design | Lug / Wafer |

| Size | A | B | C | D | E |

| 50 | 48 | 203 | 310 | 335 | 468 |

| 80 | 51 | 203 | 375 | 425 | 560 |

| 100 | 51 | 203 | 420 | 495 | 622 |

| 125 | 57 | 254 | 470 | 565 | 726 |

| 150 | 57 | 254 | 510 | 625 | 789 |

| 200 | 70 | 305 | 610 | 775 | 958 |

| 250 | 70 | 406 | 665 | 915 | 1109 |

| 300 | 76 | 406 | 755 | 1055 | 1280 |

| 350 | 76 | 508 | 885 | 1240 | 1436 |

| 400 | 89 | 508 | 900 | 1300 | 1495 |

| 450 | 89 | 508 | 1025 | 1485 | 1676 |

| 500 | 114 | 508 | 1140 | 1640 | 1891 |

| 600 | 114 | 508 | 1340 | 1960 | 2195 |

Technical Specification

| Design Std. | MSS-SP81 |

| End Eonnection | Lugged To Asme (Ansi)B 16.5 RF 150# Flanged / Wafer |

| Face to Face | MSS-SP81 |

| Testing Std. | MSS- SP81 |