Pinch Valves

Pinch Valves Manufacturer In India

Seatless and Glandless, Field replacable Elastomer Sleeve, Four reinforced lugs prevent Sleeve from collapse against vacuum, Positive Shut-off, Ends flanged & drilled to DIN, ANSI, BS 10 , IS etc.

We reserve the right to make construction and design alterations :

This Valve Incorporates all the design modifications based on our experience in the field and is of sturdy construction to handle abrasive and corrosive media. Face-to-face dimensions as per conventional pinch valves or any required length on request.

Size Range: 15mm to 300mm

This is the New Product Launch Form our New brand Name “FLOWRISE” Open Body Pinch Valves, Pinch Valve. These valves have extra Ordinary Benefits to the Users. The rubber sleeve Of these valves are Protect Form the Cast Iron Body Sealing, and give Special Life and Have a Low Weight Body so that the Client get Benefits of it in the long Height Plant…

Technical Description of Pinch Valves :

| Part | Material |

| Body | C.I. IS 210 Gr 20-25 / Cast Steel / Aluminum |

| Pinching Bars | C.I. IS 210 Gr 20-25 / Cast Steel / Aluminum |

| Sleeve | To Suit Service |

| Spindle | AISI 410 |

| Spindle | AISI 410 |

| Bridge | Cast Steel |

| Lug’s Clamp | M.S. |

| Spindle’s Clamp | G.M. |

| Tie Bars | AISI 410 |

| Key | M.S. |

| Yoke Bush | G.M. |

| Travel Limit Nut | M.S. |

| Wheel | C.I. |

| Wheel Nut | M.S. |

| Lug Clamp Scr. | M.S. |

| Spindle Clamp Scr. | M.S. |

| Set Scr. | M.S. |

Available in Natural, Neoprene, Butyl, Hypalon E.P.D.M. or blends to Suit Service.

| Size in m.m. | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| l | 108 | 124 | 133 | 152 | 165 | 197 | 222 | 260 | 311 | 362 | 412 | 527 | 640 | 760 |

| H open | 150 | 165 | 176 | 205 | 216 | 246 | 279 | 323 | 379 | 460 | 508 | 612 | 738 | 860 |

| D dia | 85 | 100 | 100 | 110 | 130 | 140 | 180 | 190 | 225 | 270 | 340 | 375 | 480 | 480 |

Available with CAM Aculator, Electric Actuator or Gear operator

Suitable Rubber Compound

- Natural

- Neoprene

- Butyle

- Nytrile

- Hypelone

- E.P.D.M

- Silicone

- Viton

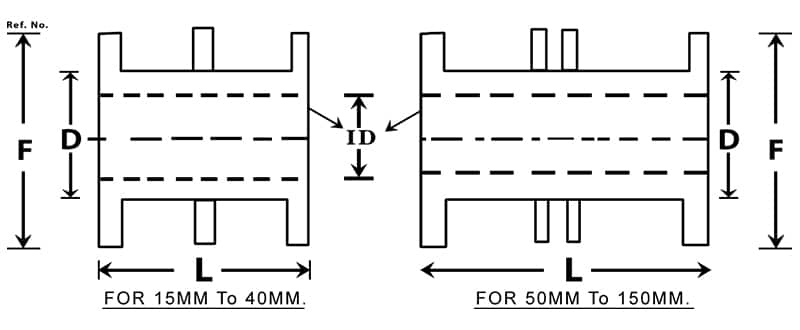

| Size | ID | D | F | L |

| 15 | 15 | 25 | 50 | 108 |

| 20 | 20 | 32 | 57 | 124 |

| 25 | 25 | 45 | 68 | 133 |

| 32 | 32 | 52 | 80 | 152 |

| 40 | 40 | 65 | 87 | 165 |

| 50 | 50 | 76 | 155 | 197 |

| 65 | 65 | 82 | 175 | 222 |

| 80 | 80 | 108 | 190 | 260 |

| 100 | 100 | 130 | 210 | 311 |

| 125 | 125 | 157 | 240 | 362 |

| 150 | 150 | 193 | 278 | 412 |

* All Diemensions are in M.M.

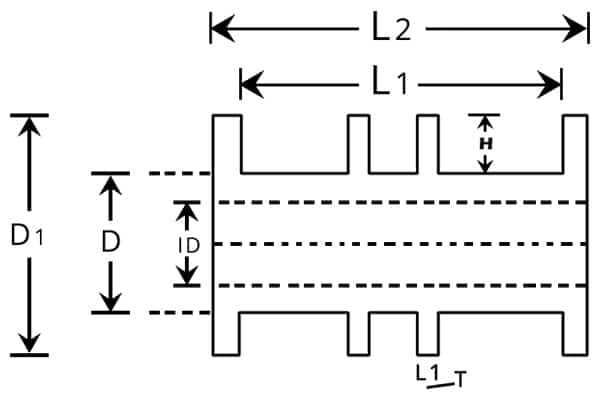

| Size | ID | D | D1 | L1 | L2 | H | T |

| 50 | 50 | 76 | 155 | 179 | 197 | 55 | 7 |

| 65 | 65 | 82 | 175 | 203 | 222 | 60 | 8 |

| 80 | 80 | 108 | 190 | 240 | 260 | 66 | 8 |

| 100 | 100 | 130 | 210 | 291 | 311 | 68 | 8 |

| 125 | 125 | 157 | 240 | 340 | 362 | 80 | 9 |

| 150 | 150 | 180 | 292 | 388 | 412 | 90 | 10 |

| 200 | 200 | 235 | 330 | 503 | 527 | 95 | 10 |

| 250 | 250 | 290 | 385 | 612 | 640 | 105 | 10 |

| 300 | 300 | 339 | 435 | 750 | 778 | 120 | 11 |

* All Diemensions are in M.M.

Other Polymer Sleeve Valve As Under

General Features of Pinch Valves

“FLOWRISE” make Valve sleeve is self-cleaning due to its unobstructed design and Smooth action. “FLOWRISE” valves will not jam or Hard, even with high-percent solids.

Abrasion and Reinforced Canvas Rubber Sleeve:

Flowrise Valve high-grade elastomer (Hard) sleeves outperform metal valves in abrasion and corrosion. The sleeve is the main part of the pinch valve exposed to the process fluid, making it a cost-effective alternative to valves constructed of exotic body Materials, Easy and quick sleeve and bush replacement

Free -cMaintenance:

The operating mechanism of the Valve is isolated from the process fluid, virtually eliminating any wearing issues. This is also why the torque to close a Valve remains constant over time, even when the valve has not been exercised. No product contact with theValve body

Seals Drop-Tight :

The thickness of elastomer Tube of the Valve sleeve forms around entrapped solids and seals drop-tight without damage to the Rubber sleeve.

Modulating Provider:

The smooth unobstructed sleeve contour minimizes turbulence even when throttled. Reduced port sleeves are available in double wall flow rates and process conditions.

Interchangeability:

Many Valve styles have common lengths with Plug, Gate, and Diaphragm Valves, making them ideally suited for plant upgrade applications.

Versatile And Modular Construction:

The Valve design enables the customer to choose the sleeve material (Neoprene.Hyplon.EPDM) and type of valve body construction (Open / Close Body), as well as any customized actuators and/or controls. Many designs allow the customer to change the actuator type even while the valve is in service.

Cost-Effective Products:

An optimal design does not necessarily mean higher pressure or temperature ratings, because these features typically increase the product’s cost and maintenance. And try to give a Most Competitive Coast to our Client, Our abrasion and corrosion-resistant materials can outperform even the most exotic metals. Our large making and Develop in ISO 9001:2000 certified manufacturing Unit also mean Faster deliveries, as well as top for quality products Pinch Valves and Service Provider.

Materials of Construction for Rubber Sleeve of Pinch Valve: Neoprene:

Resists alkalis, inorganic acids, and salt solutions. Flame-retardant, as well as abrasion and weather resistant. Good resistance moderate resistance to petroleum oils. Effective operating range from -10ºC to 220ºC.

Butyl:

Lowest permeability, very good resistance to water, heat, fats, alkalis, sunlight, abrasion, and oxygenated solvents. Effective operating range from -30ºCto 300ºC

Hypalon:

Superior weather resistance, flame retardant, good abrasion resistance, and excellent resistance to acids, alkalis, and oxidation. Effective operating range from -10ºC to 250ºC

Nitrile:

Good resistance to mineral and vegetable oils, greases, hydrocarbon solvents, dilute acids, and alkalis. Effective operating range from -10ºC to 210ºC.

EPDM:

Outstanding water, vapor, and weather resistance. Good resistance to heat, alkalis, sunlight, and oxygenated solvents. Don’t use it with petroleum oil service. Good general purpose elastomer with an effective operating range from -30ºC to 350ºC